Heat Transfer DTF Film (Direct To Film)

Our advantage is:

1. The largest DTF film factory in China, all sizes can be customized;

2. Stable quality with a shelf life of 1 year, while many factories have a shelf life of 3-5 months;

3. Fast delivery time, 5-7 days for delivery;

4. Do not use second-hand materials, maintain value and quantity;

5. Top 10 brands, able to take responsibility for any issues to the end

6.In general, heat transfer dtf film can be said that the DTF process removes almost all the limitations found in other textile printing processes, especially when it comes to the selection of print fabrics. Since no pre-processing is required, in many cases the overall cost of printing is reduced, resulting in higher profits.

If you want to learn more about product details, you can contact us

Cowint DTF Film Specification

| Size | A3/A4, 30cm/45cm/60cm/80cm*100m (11.8"/17.7"/23.6"/31.4"*328ft) |

| Peel | Hot Peel / Cold Peel / Instant Peel |

| Coating | Single-side matte/double-side matte |

| Temperature | 130-150℃ |

| Press time | 10-15s |

| Ink load | Maximum 400% |

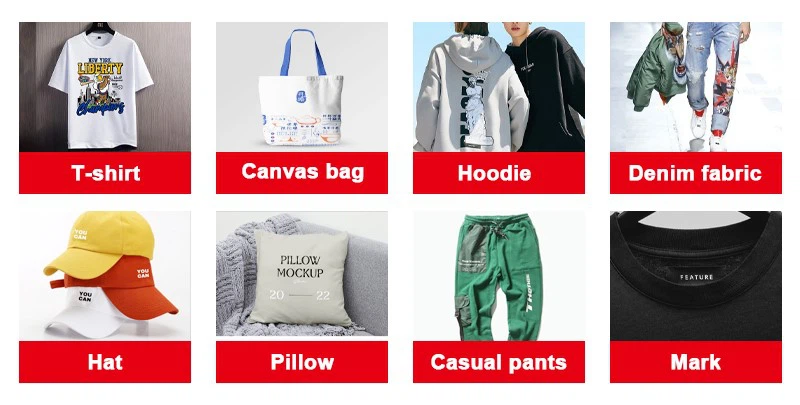

| Application | T-shirts, bags, shoes, socks, leather and more |

Cowint DTF Film Product Describtion

Direct-to-film, or DTF, is a process that uses heat to transfer prints to fabric or other substrates, unlike DTG, which works only on cotton. The DTF process can be used on cotton, polyester, cotton/polyester blends and many fabrics without refrigeration.

Cowint DTF Film Product Advantage

1.5 coating layer 2.Good ductility 3.bright colors 4.wide coverage

5.good elasticity 6.good compatibility 7.strong washing performance

8.Our premium heat transfer direct to films have very high ink absorption levels and produce highly vivid prints.

Cowint DTF Film 5-coating layer structure

Cowint's DTF film has a unique 5-layer structure. Generally, the DTF film of other companys have only two layers of coating: release layer and ink absorption layer. Our film has added a protective layer for ink dry and wet rubbing fastness and two ink absorption layers. In this way, our DTF film has the characteristics that the ink absorption performance during printing is much better than other companies. At the same time, it has high dry and wet rubbing fastness after transfer.

Cowint DTF Film Comparison chart

Peel Off Easy to tear

Easy to separate and clean Difficult to separate and tear clean

Oil Return Easy to return oil

Easy to separate and clean Difficult to separate and tear clean

Chromatic aberration The color is not bright

excellent color brilliance Difficult to separate and tear clean

EDGE Unclear edge

There's no imaginary edge Visible shirt hem

Sticky powder Serious powder sticking

There was no sign of sticky powder Obvious signs of sticky powde

Cowint DTF Film Application scenarios

In addition to its excellent color performance, DTF FILM can also be applied to a variety of high temperature resistant

fabric materials, such as socks, canvas shoes, hats, T-shirts, canvas bags and other commodities. Small studios

have the need to print a small amount of various peripheral products. The cheap price of offset heat press

(DTF direct-injection film printer)and the simple operation process can help these companies to print their own products.

Cowint DTF Film Workshop

DTF FILM has undergone three processes of coating, dispersion and drying.

Our process flow is as long as 40 meters, and the average factory is 25 meters.

The film coating is more uniform and the process is more stable;

Cowint has been a manufacturer of transfer paste for 27 years. All the raw materials of the coating

are developed by ourselves. We know the formula better, and we know the release degree of the film better.

We produce coating raw materials by ourselves, which can keep the quality stable and control the cost.

How To Use DTF film

1.Prepare the heat transfer membrane

2.Input the design drawing you want to print into the transfer machine for printing

3.The printed film is shaken evenly through the powder shaking machine

4.Evenly spread hot melt powder film through the press, the pattern printed on the clothes, about 10-15 seconds can be

5.And you're done

Matters needing attention

-Storage environment: Relative humidity 35-65%, temperature 10-30°C, sealed indoor storage, avoid direct sunlight, shelf life 1 year.

- Washing Precautions:

We recommend washing the transferred shirts separately with normal detergent and cold water.

Use washing cycles (400-800 rpm).

After washing, if the image shows signs of shedding, you can cover the image with parchment paper and iron it again. Do not iron the transfer part directly with an iron.

If you want to learn more about product details, you can contact us

Hot Tags: Cowint DTF Film Heat Transfer Direct To Film, China, suppliers, manufacturers, factory, customized, wholesale, Flavours Print Paste, Transfer Film, Swimming Suit Print, Water proof Nylon Print, Table Glue Paper, Imitation Gold Silver Printing

![[NEW] DTF Printer(XP600)](/uploads/202229042/small/inkjet-printers10241246388.png?size=78x0)

![[NEW] Offset Inkjet Printer Heat Transfer Printing Machine](/uploads/202129042/small/offset-heat-transfer-machine29057275291.jpg?size=78x0)

![[NEW] Inkjet Printer Heat Transfer Printing Digital Machine Introduction](/uploads/202129042/small/heat-transfer-printing-machine-introduction10054568847.jpg?size=78x0)